Ultrafiltration (UF) is a pressure driven membrane separation process. Thanks to its nano-sized pores, UF membrane is widely known as powerful system for turbidity removal and desinfection in water treatment. Since it is operated in low pressure, which means low energy consumption, and yet relatively chemical-free, UF seems to be both economically and environmentally feasible.

1. Modular UF Package

Modular UF Package is highly recommended for producing free pathogen water in small capacity. Its compact design resulting in small footprint.

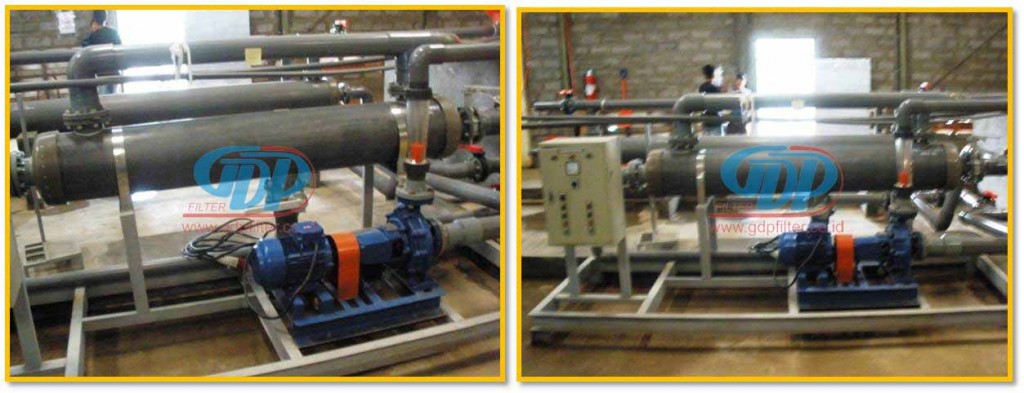

2. Non-Modular UF Train

Non-modular membrane system has been developed and patented by GDP Filter Indonesia. This invention relates generally to the improvement in Multi-Bore Capillary Membrane fiber or hollow fiber cartridge assembly for minimizing membrane cost in larger plant.

Membrane surface area in the module can be adjusted to desired capacity, so membrane in the previous modular process can be simplified in a piece of equipment. This system has been proven to give better performance with lower investment cost in large water treatment unit using multi-bore capillary ultrafitration membrane.

The system is designed to use only 1 pump for either feed circulation or backwash to minimize investment cost.

Advantages :

- Easier operation,

- Less instruments,

- Simple piping and installation,

- More economical membrane process in larger capacity.

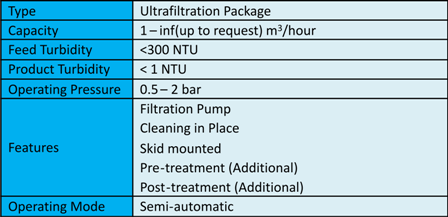

Product Specification :